Exceptional comfort

Herausragender Komfort

|

Twelve cylinders in the Audi Q7

Audi has stood

at the forefront of diesel technology for the last three decades. The Ingolstadt

brand now presents a further world first - the first V12 diesel engine in

a passenger car.

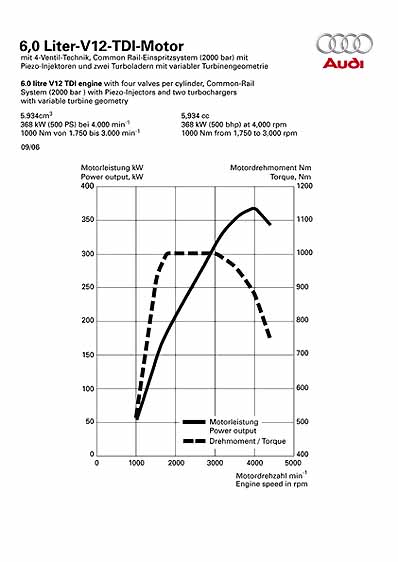

The new Audi Q7 V12 TDI is powered by a twelve-cylinder diesel

engine containing a wealth of pioneering technology. With an outstanding

500 PS and 1,000 Nm of torque, the six-litre engine of the high-performance

SUV provides the driving performance of a sports car. Sprinting from 0 to

100 km/h in just 5.5 seconds and achieving an electronically governed top

speed of 250 km/h, the Audi Q7 V12 TDI is catapulted into the echelons of

top-class sports cars. New horizons have been set in the diesel market thanks

to this outstanding power. None of our competitors can offer a comparable

engine. The big performance SUV from Audi accelerates with impressive ease.

Superior power reserves in any situation are provided by the world's first

2,000 bar Bosch Common Rail system. The ultra-modern piezo-injection system

offers impressive acoustics at the highest levels of driving comfort. The

new six-speed tiptronic gearbox, which features extensive reinforcements,

shifts quickly and comfortably. It transfers the enormous power to the quattro

permanent four-wheel drive system. The new Audi Q7 V12 TDI has an average

fuel consumption of just 11.9 litres per 100 kilometres. All diesel engines

from Audi are highly dynamic thanks to their high performance and high torque

characteristics. Audi has often proved its sporty character in series production,

most recently through the six and eight-cylinder 3.0 TDI and 4.2 TDI engines.

Audi also rewrote the record books earlier this year on the racetrack. Following

its debut in Sebring, Florida, the premium R10 prototype sports car won every

long-distance race it entered. These included the Le Mans 24 Hours road race,

probably the most difficult race in the world for both man and machine. The

V12 race engine in the R10 squeezed 650 bhp from its 5.5-litre engine capacity,

reaching a top speed of 330 km/h. The power and endurance of the R10 was

an immediate hit with fans and experts alike. However, what completely surprised

them was the sound of the engine: unlike most racing engines, the powerful

Audi diesel engine runs whisper-quiet. Transferring race car technology into

series production is an Audi tradition. The FSI engine in the predecessor

to the R10, the R8, notched up five victories in Le Mans with its petrol

direct injection. Audi has already transferred FSI performance to the production

line. The most recent examples of this are the high-revving V8 in the RS

4 and the V10 FSI in the S6 and S8. The new Audi Q7 V12 TDI is powered by a twelve-cylinder diesel

engine containing a wealth of pioneering technology. With an outstanding

500 PS and 1,000 Nm of torque, the six-litre engine of the high-performance

SUV provides the driving performance of a sports car. Sprinting from 0 to

100 km/h in just 5.5 seconds and achieving an electronically governed top

speed of 250 km/h, the Audi Q7 V12 TDI is catapulted into the echelons of

top-class sports cars. New horizons have been set in the diesel market thanks

to this outstanding power. None of our competitors can offer a comparable

engine. The big performance SUV from Audi accelerates with impressive ease.

Superior power reserves in any situation are provided by the world's first

2,000 bar Bosch Common Rail system. The ultra-modern piezo-injection system

offers impressive acoustics at the highest levels of driving comfort. The

new six-speed tiptronic gearbox, which features extensive reinforcements,

shifts quickly and comfortably. It transfers the enormous power to the quattro

permanent four-wheel drive system. The new Audi Q7 V12 TDI has an average

fuel consumption of just 11.9 litres per 100 kilometres. All diesel engines

from Audi are highly dynamic thanks to their high performance and high torque

characteristics. Audi has often proved its sporty character in series production,

most recently through the six and eight-cylinder 3.0 TDI and 4.2 TDI engines.

Audi also rewrote the record books earlier this year on the racetrack. Following

its debut in Sebring, Florida, the premium R10 prototype sports car won every

long-distance race it entered. These included the Le Mans 24 Hours road race,

probably the most difficult race in the world for both man and machine. The

V12 race engine in the R10 squeezed 650 bhp from its 5.5-litre engine capacity,

reaching a top speed of 330 km/h. The power and endurance of the R10 was

an immediate hit with fans and experts alike. However, what completely surprised

them was the sound of the engine: unlike most racing engines, the powerful

Audi diesel engine runs whisper-quiet. Transferring race car technology into

series production is an Audi tradition. The FSI engine in the predecessor

to the R10, the R8, notched up five victories in Le Mans with its petrol

direct injection. Audi has already transferred FSI performance to the production

line. The most recent examples of this are the high-revving V8 in the RS

4 and the V10 FSI in the S6 and S8.

Pioneering technical

performance

The new series-production V12 TDI, assembled in our plant in

Györ, Hungary, reaches a still outstanding level of "only" 500 bhp.

When designing the engine, it was kept in mind that the six-litre engine

would be a derivative of the current family of Audi V-engines, which up to

now were limited to six, eight and ten cylinders. The basic findings from

the race car were of course transferred to the series-production engine.

The V12 TDI aggregate has a cylinder clearance of 90 mm, which is standard

for engines of this type. Nonetheless, the engine has a cylinder angle of

60° instead of 90°, leading to an elimination of inertia in this

type of V12 design. Driving comfort is thus ensured in every situation. The

total engine capacity of 5,934 cm3 is derived from a bore measurement of

83 mm and a stroke of 91.4 mm, exactly the same as that of the 3.0 TDI. The

large diesel engine is extremely compact. Measuring 684 mm in length, it

is only 166 mm longer than the V8 TDI. These dimensions are the primary

requirement for integrating the V12 into the Audi Q7. The crankcase of the

V12 TDI is constructed from cast-iron with vermicular graphite. This high-tech

material, known as GJV-450, has already been used in the V6 and V8 models.

Produced in a patented casting procedure, GJV-450 is around 40 % more rigid

and 100 % more fatigue-resistant than grey cast iron. This allowed the developers

to reduce the wall thickness. The weight potential compared to conventional

grey cast iron is around 15 %. The crankshaft, forged from a chrome and

molybdenum steel alloy, is held by an extremely rigid main bearing bracket

made from cast iron reinforced by nodular graphite. The forged piston rods

are cracked, whilst the forged pistons are made from aluminium. Both cylinder

heads are composed of three main elements. The lower section is made from

a highly durable and light aluminium alloy where the intake and escape channels

are integrated. The upper section guides the flow of engine oil, whilst both

camshafts are stored within a reinforcing ladder frame. The valves are actuated

using low-friction roller cam followers with a compression ratio of 16:1.

The engine characteristic swirl variations of combustion air were taken from

the V6 and V8 TDI engines. The optimum swirl with respect to emissions and

simultaneous high performance can therefore be set. The new series-production V12 TDI, assembled in our plant in

Györ, Hungary, reaches a still outstanding level of "only" 500 bhp.

When designing the engine, it was kept in mind that the six-litre engine

would be a derivative of the current family of Audi V-engines, which up to

now were limited to six, eight and ten cylinders. The basic findings from

the race car were of course transferred to the series-production engine.

The V12 TDI aggregate has a cylinder clearance of 90 mm, which is standard

for engines of this type. Nonetheless, the engine has a cylinder angle of

60° instead of 90°, leading to an elimination of inertia in this

type of V12 design. Driving comfort is thus ensured in every situation. The

total engine capacity of 5,934 cm3 is derived from a bore measurement of

83 mm and a stroke of 91.4 mm, exactly the same as that of the 3.0 TDI. The

large diesel engine is extremely compact. Measuring 684 mm in length, it

is only 166 mm longer than the V8 TDI. These dimensions are the primary

requirement for integrating the V12 into the Audi Q7. The crankcase of the

V12 TDI is constructed from cast-iron with vermicular graphite. This high-tech

material, known as GJV-450, has already been used in the V6 and V8 models.

Produced in a patented casting procedure, GJV-450 is around 40 % more rigid

and 100 % more fatigue-resistant than grey cast iron. This allowed the developers

to reduce the wall thickness. The weight potential compared to conventional

grey cast iron is around 15 %. The crankshaft, forged from a chrome and

molybdenum steel alloy, is held by an extremely rigid main bearing bracket

made from cast iron reinforced by nodular graphite. The forged piston rods

are cracked, whilst the forged pistons are made from aluminium. Both cylinder

heads are composed of three main elements. The lower section is made from

a highly durable and light aluminium alloy where the intake and escape channels

are integrated. The upper section guides the flow of engine oil, whilst both

camshafts are stored within a reinforcing ladder frame. The valves are actuated

using low-friction roller cam followers with a compression ratio of 16:1.

The engine characteristic swirl variations of combustion air were taken from

the V6 and V8 TDI engines. The optimum swirl with respect to emissions and

simultaneous high performance can therefore be set.

Ultra-modern

injection technology

Like most Audi V-engines, the maintenance-free chain drive is

located on the back of the engine in a space-saving arrangement. A new layout

is used in the new V12 TDI. The chain wheel of the crankshaft locks into

the gearwheel. From here two simplex chains drive the camshaft. Two further

chains drive the oil pump and both high-pressure pumps in the common rail

injection system. Both new double stamped high-pressure pumps are part of

the new common rail injection system developed by the specialists at Bosch.

Both pumps amass up to 2,000 bar of pressure in the rails; only 1,600 bar

was usually achieved up to now. The piezo injectors, with their eight-hole

jets, have also been radically updated. An optimal spray is created in the

combustion chamber through the high pressure. This in turn allows the ignition

process to take place quicker and more homogenously, leading to a much better

sound. The efficient combustion also improves performance whilst reducing

emissions and fuel consumption. The current generation of inline injectors

use the piezo effect. When an electric current is created, piezo crystals

expand in milliseconds. This expansion is then directly transported (inline)

by the V12 TDI injectors - containing over one hundred piezo plates - to

the injection nozzle needles without the use of mechanisms in between. The

number of injection processes per power stroke can be widely varied using

piezo technology, in the case of the V12 TDI up to five injections. In addition

to the main injection, pre and post-injections are possible. Pre-injections

reduce the acoustic hardness of the combustion procedure. Post-injections

serve to increase the temperature of the emissions, helping regeneration

of both standard-fit particulate filters. Both turbochargers can be found

on the exterior of the V-engine, each supplied with a cylinder bank. Thanks

to its adjustable guide vane geometry, the complete gas emission stream is

always fed through the turbines. The chargers respond even at low levels

of revolution and reach high levels of efficiency. Both turbochargers amass

a charge pressure of up to 2.6 bar and are a key aspect of the exceptional

torque levels of 1,000 Nm that are supplied to the V12 TDI constantly between

1,750 and 3,000 rpm. With its 368 kW (500 bhp), the diesel reaches a specific

performance of 62 kW (84.3 bhp) per litre of engine capacity. Two large charge

air coolers reduce the temperature of the compressed air. The V12 comes with

a double-flow exhaust system with two particulate filters. The suction unit

is built in a similar way - each cylinder bank contains an air filter behind

which an air mass meter is stored. Two control units manage what happens

within the engine according to the master-slave concept. The Audi Q7 V12

TDI will conform to the Euro 5 emissions class which will come into force

in 2010 and demand a reduction of nitrogen oxide emissions. Aside from the

precise analysis of the fuel injection system through the common rail system,

the Audi engineers have focused especially on exhaust gas recirculation.

At partial load, up to 50 % of emissions are recirculated through the air

intake in order to reduce nitrogen oxide emissions. The large-dimension

recirculation system is stored in the upper section of the V cylinder and

includes a water cooler which reduces emission temperature significantly. Like most Audi V-engines, the maintenance-free chain drive is

located on the back of the engine in a space-saving arrangement. A new layout

is used in the new V12 TDI. The chain wheel of the crankshaft locks into

the gearwheel. From here two simplex chains drive the camshaft. Two further

chains drive the oil pump and both high-pressure pumps in the common rail

injection system. Both new double stamped high-pressure pumps are part of

the new common rail injection system developed by the specialists at Bosch.

Both pumps amass up to 2,000 bar of pressure in the rails; only 1,600 bar

was usually achieved up to now. The piezo injectors, with their eight-hole

jets, have also been radically updated. An optimal spray is created in the

combustion chamber through the high pressure. This in turn allows the ignition

process to take place quicker and more homogenously, leading to a much better

sound. The efficient combustion also improves performance whilst reducing

emissions and fuel consumption. The current generation of inline injectors

use the piezo effect. When an electric current is created, piezo crystals

expand in milliseconds. This expansion is then directly transported (inline)

by the V12 TDI injectors - containing over one hundred piezo plates - to

the injection nozzle needles without the use of mechanisms in between. The

number of injection processes per power stroke can be widely varied using

piezo technology, in the case of the V12 TDI up to five injections. In addition

to the main injection, pre and post-injections are possible. Pre-injections

reduce the acoustic hardness of the combustion procedure. Post-injections

serve to increase the temperature of the emissions, helping regeneration

of both standard-fit particulate filters. Both turbochargers can be found

on the exterior of the V-engine, each supplied with a cylinder bank. Thanks

to its adjustable guide vane geometry, the complete gas emission stream is

always fed through the turbines. The chargers respond even at low levels

of revolution and reach high levels of efficiency. Both turbochargers amass

a charge pressure of up to 2.6 bar and are a key aspect of the exceptional

torque levels of 1,000 Nm that are supplied to the V12 TDI constantly between

1,750 and 3,000 rpm. With its 368 kW (500 bhp), the diesel reaches a specific

performance of 62 kW (84.3 bhp) per litre of engine capacity. Two large charge

air coolers reduce the temperature of the compressed air. The V12 comes with

a double-flow exhaust system with two particulate filters. The suction unit

is built in a similar way - each cylinder bank contains an air filter behind

which an air mass meter is stored. Two control units manage what happens

within the engine according to the master-slave concept. The Audi Q7 V12

TDI will conform to the Euro 5 emissions class which will come into force

in 2010 and demand a reduction of nitrogen oxide emissions. Aside from the

precise analysis of the fuel injection system through the common rail system,

the Audi engineers have focused especially on exhaust gas recirculation.

At partial load, up to 50 % of emissions are recirculated through the air

intake in order to reduce nitrogen oxide emissions. The large-dimension

recirculation system is stored in the upper section of the V cylinder and

includes a water cooler which reduces emission temperature significantly.

The design

The Audi Q7 V12 TDI is impressive not only with regard to technology but

also in terms of appearance. The most striking visual changes to the Audi

Q7 are the underbody panels at the front and rear. The chrome-plated single-frame

radiator grille evokes the tradition of the Audi S6 and S8. These two cars,

with their V10 FSI engines, are the top sports models in their class. The

V12 TDI features a powerful braking system which is every bit its equal.

Vorsprung durch

Technik

Diesel milestones from Audi

A further milestone in diesel technology has been reached with the advent

of the new V12 TDI. The Ingolstadt brand has been the pioneer in the diesel

domain for over three decades. In 1978, Audi introduced the Audi 100, the

world's first five-cylinder diesel. The first TDI engine in motoring history

was introduced in the successor model in 1989. The 2.5-litre five-cylinder

engine offered 88 kW (120 bhp) and 261 Nm of torque, and catapulted diesel

motoring into whole new dimensions. In 1994, an expanded version was produced

with 103 kW (140 bhp). The engine was also available with the option of

four-wheel drive - the first TDI quattro. At the same time, a new four-cylinder

diesel engine was introduced in the Audi 100 and Audi 80, the now legendary

1.9 TDI with 66 kW (90 bhp). Towards the end of 1995, the four-cylinder achieved

new heights of 85 kW (115 bhp) through the use of pump-jet injection. Just

over a year later at the beginning of 1997, the world's first 2.5 V6 TDI

made its debut. This engine came with four valves per cylinder and reached

110 kW (150 bhp). With a top speed of 220 km/h the Audi A8 became the quickest

series-production diesel on the market. The first eight-cylinder TDI followed

in 1999, a V8 with a displacement of 3.3 litres. The 3.0 TDI was introduced

in the spring of 2004, the first V6 diesel engine with inline piezo injectors

in the common rail system. The 4.2-litre TDI currently spearheads the TDI

range from Audi. It was first introduced last year in the A8. Every third

A8 buyer in Germany decided opted for the V8. The V8 TDI will also become

available for the Audi Q7 during the first half of 2007.

The equipment, data and prices stated

here refer to the model range offered for sale in Germany. Subject to amendment;

errors and omissions excepted.

AUDI AG, Kommunikation Produkt

und Technik

AUDI AG, Communication Product and Technology

Ingolstadt, September 12, 2006 |

BACK TO TOP

HOME |

CARS AND VEHICLES |

AUDI-MODELS |

MOTORSPORTS | HOME |

CARS AND VEHICLES |

AUDI-MODELS |

MOTORSPORTS |

| HOME |

MODELLE |

AUDI-MODELLE |

MOTORSPORT |

MOBILER ALLTAG |

© Copyright 2006, motormove

online. All rights reserved.

|