The

Stuttgart-based brand

Sporty design

through and through

Ein durch und durch sportlicher

Auftritt

ZUR DEUTSCHEN VERSION |

Mercedes-Benz SLR McLaren 722 Edition

Mercedes-Benz

SLR McLaren 722 Edition Motorracing blood coursing through its veins

Stuttgart/Dubai - The new Mercedes-Benz SLR McLaren 722 Edition displays

thoroughbred motorracing credentials. Featuring more than 300 modified

components, the super sports car serves up a boost in output, more dynamic

chassis tuning, improved aerodynamics and distinctly sporty interior appointments

to thrill even the most demanding of sportscar enthusiasts.

The flawless roads which today lead through the

desert next to Dubai are ideal for demonstrating the pedigree sporting

performance that characterises the

Mercedes-Benz SLR McLaren 722

Edition. Dubai is the up-and-coming business centre of the United Arab

Emirates (UAE). It is the setting for the world's most ambitious construction

projects, including the man-made "Palm Jumeirah" island, and over the course

of recent decades many wealthy sheikhs have become avid automobile aficionados.

It is this flair for the exceptional that links the desert city on the Persian

Gulf and its inhabitants with the Mercedes-Benz SLR McLaren 722 Edition premium

sports car. The new SLR 722 Edition model variant from Mercedes-Benz evokes

memories of a particularly special victory achieved in 1955 by the British

motorracing legend Stirling Moss and his co-pilot Dennis Jenkinson at Mille

Miglia – the classic Italian endurance race – behind the wheel

of a Mercedes-Benz 300 SLR with start number 722 (denoting the car's start

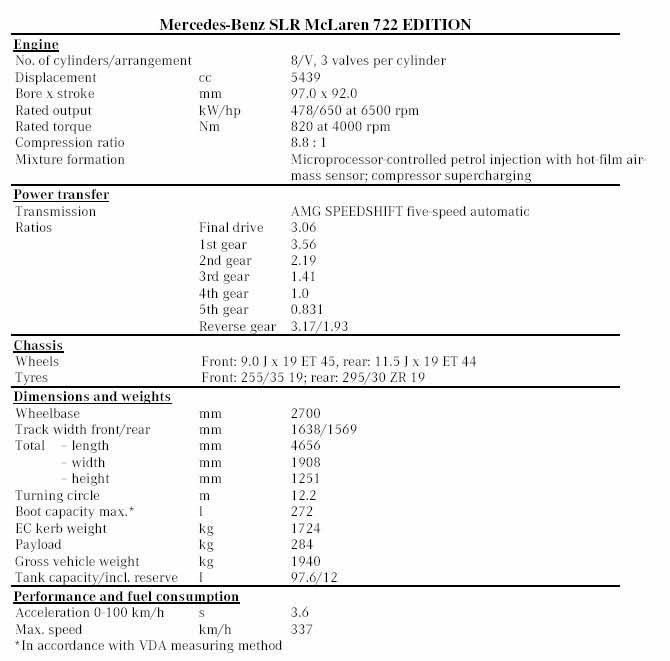

time of 7.22 a.m.). Boasting an impressive output of 478 kW/650 hp, the new

SLR McLaren 722 Edition super sports car not only outperforms its historic

forefather, it even outstrips the scintillating peak performance of the current

SLR model. The new limited-edition series – only 150 models are being

produced, for the most part handcrafted, at the McLaren Formula 1 works in

Woking – is the brand's response to calls from highly discerning SLR

customers for even more sportiness combined with the same high level of everyday

practicality. At the heart of the SLR 722 Edition is a 5.5-litre supercharged

V8 assembled by hand at the Mercedes-AMG engine workshops in Affalterbach,

Germany, based on the "One man, one engine" principle. Among the high-performance

powerplant's major strengths are its exceptionally spontaneous response to

accelerator pedal movements, high torque and that unmistakable V8 sound. The flawless roads which today lead through the

desert next to Dubai are ideal for demonstrating the pedigree sporting

performance that characterises the

Mercedes-Benz SLR McLaren 722

Edition. Dubai is the up-and-coming business centre of the United Arab

Emirates (UAE). It is the setting for the world's most ambitious construction

projects, including the man-made "Palm Jumeirah" island, and over the course

of recent decades many wealthy sheikhs have become avid automobile aficionados.

It is this flair for the exceptional that links the desert city on the Persian

Gulf and its inhabitants with the Mercedes-Benz SLR McLaren 722 Edition premium

sports car. The new SLR 722 Edition model variant from Mercedes-Benz evokes

memories of a particularly special victory achieved in 1955 by the British

motorracing legend Stirling Moss and his co-pilot Dennis Jenkinson at Mille

Miglia – the classic Italian endurance race – behind the wheel

of a Mercedes-Benz 300 SLR with start number 722 (denoting the car's start

time of 7.22 a.m.). Boasting an impressive output of 478 kW/650 hp, the new

SLR McLaren 722 Edition super sports car not only outperforms its historic

forefather, it even outstrips the scintillating peak performance of the current

SLR model. The new limited-edition series – only 150 models are being

produced, for the most part handcrafted, at the McLaren Formula 1 works in

Woking – is the brand's response to calls from highly discerning SLR

customers for even more sportiness combined with the same high level of everyday

practicality. At the heart of the SLR 722 Edition is a 5.5-litre supercharged

V8 assembled by hand at the Mercedes-AMG engine workshops in Affalterbach,

Germany, based on the "One man, one engine" principle. Among the high-performance

powerplant's major strengths are its exceptionally spontaneous response to

accelerator pedal movements, high torque and that unmistakable V8 sound. |

Crankcase with dry-sump

lubrication

The powerplant's entire engine block with its enclosed

crankcase sump is made from cast aluminium. Each crankshaft is precision-weighted

and revolves in five bearings made from a high-durability material to enable

sustained transmission of the tremendous forces emanating from the supercharged

engine. The forged pistons are only manufactured in extremely small numbers.

Just like the forged lightweight connecting rods, the pistons are measured

and weighed with utmost accuracy before being assigned to individual engines.

This keeps any mass balancing tolerances to an absolute minimum. The pistons

slide inside extremely durable, wear-resistant, low-friction cylinder barrels

made from a special compound which is otherwise only found in race car engines.

Twin oil injection is used for effective piston cooling. The oil cooling

technology employed for the power unit as a whole also draws on the brand's

racetrack experience: a sophisticated dry-sump lubrication system with a

capacity of around eleven litres combines with a five-speed oil suction pump

and a two-speed oil pressure pump to guarantee reliable lubrication under

all driving conditions. One important knock-on effect of this dry-sump

lubrication technology, which is again normally exclusive to race cars, is

that the engine height can be kept low, allowing it to be installed deeper

down in the engine compartment: the result is a low centre of gravity that

fosters dynamic handling. The powerplant's entire engine block with its enclosed

crankcase sump is made from cast aluminium. Each crankshaft is precision-weighted

and revolves in five bearings made from a high-durability material to enable

sustained transmission of the tremendous forces emanating from the supercharged

engine. The forged pistons are only manufactured in extremely small numbers.

Just like the forged lightweight connecting rods, the pistons are measured

and weighed with utmost accuracy before being assigned to individual engines.

This keeps any mass balancing tolerances to an absolute minimum. The pistons

slide inside extremely durable, wear-resistant, low-friction cylinder barrels

made from a special compound which is otherwise only found in race car engines.

Twin oil injection is used for effective piston cooling. The oil cooling

technology employed for the power unit as a whole also draws on the brand's

racetrack experience: a sophisticated dry-sump lubrication system with a

capacity of around eleven litres combines with a five-speed oil suction pump

and a two-speed oil pressure pump to guarantee reliable lubrication under

all driving conditions. One important knock-on effect of this dry-sump

lubrication technology, which is again normally exclusive to race cars, is

that the engine height can be kept low, allowing it to be installed deeper

down in the engine compartment: the result is a low centre of gravity that

fosters dynamic handling. |

Screw compressor power

Efficient cylinder charging is the task of a belt-driven compressor with

two screwshaped aluminium rotors that are Teflon-coated in the interests

of keeping friction low. In order to keep the engine running as efficiently

as possible at all times, the AMG engineers have devised an intelligent engine

management system which independently determines when to deploy the screw

compressor as the engine's rev speed and load change. Consequently, the

supercharger is only called into action when it is really needed. Notwithstanding

this, however, maximum power is always available the instant the driver summons

it by opening the throttle. Apart from the compressor, the engine's electronics

monitor all of the other variables which are relevant to its operation. At

the same time, they ensure optimum operation of the intercoolers' water circuit.

After all, efficient cooling of the charge air is a vital ingredient for

high performance. The intercoolers operate based on the extremely efficient

air-to-water heat exchanger principle: the air which has been compressed

by the compressor, causing it to heat up, is directed through a separate

water circuit to cool it down again. This enables the eight-cylinder powerplant

to maximise its output and torque delivery.

Manual transmission mode for shift

times worthy of a race car

High performance has also been ingrained into the five-speed automatic

transmission, which was developed in-house at Mercedes-Benz and has already

featured in a number of exceptionally powerful models. It has been optimised

to enable it to handle the awesome torque on tap and also offers drivers

the possibility of varying the gearshift characteristics. The transmission

directs the engine's power to the differential and the rear wheels via a

precision balanced drive train made from aluminium and steel. The interplay

of the engine with the gearshift was also subject to modification. For each

of the individually selectable transmission modes – M (Manual) and S

(Sport) on the one hand and C (Comfort) on the other – there is now

a different accelerator pedal characteristic curve, which has been optimised

in line with the varying operating conditions. The end result is an extremely

impressive set of performance figures, even by high-end super sports car

standards: the SLR 722 Edition completes the sprint from 0 to 100 km/h in

a breathtaking 3.6 seconds (SLR 3.8 seconds), with the speedometer needle

proceeding to pass the 200 km/h mark in a mere 10.2 seconds (SLR 10.6 seconds)

and the 300 km/h mark in just 28.0 seconds (SLR 28.8 seconds). Plus, the

top speed of 337 km/h is even higher than that of the current SLR (334 km/h).

New chassis set-up for further enhanced

handling dynamics

One of the main driving forces behind the enhanced

performance of the SLR 722 Edition is the retuned chassis. Development work

at McLaren's Formula 1 headquarters was based on the set-up of the SLR's

proven aluminium chassis, that is itself the handiwork of experienced race

car developers: wheel guidance is the task of double wishbones at both the

front and rear. The bottom links are arranged in such a way that the wheels

receive a negative camber when the springs compress or when cornering at

speed. This guarantees optimum contact with the road in any situation. Meanwhile,

the axle technology also minimises the degree of diving and squatting while

braking heavily and accelerating respectively. The axle's wishbones are made

from forged aluminium, while cast aluminium is used for the wheel carriers.

This lightweight material boasts a host of advantages compared to conventional

steel constructions, including the far superior response of the suspension

and damping that results from the reduced weight. The relatively long wheelbase

of 2700 millimetres likewise contributes to the exemplary handling

characteristics, with the most notable benefit being the outstanding

straight-line stability, while the wide track combines with the low centre

of gravity to enable high cornering speeds. The chassis construction has

the anti-roll bar positioned above the front axle where it is controlled

via rocker arms, just like on a Formula 1 car. With this setup , the anti-roll

bar does not take up any additional installation space. In this way, the

smooth lines of the underside of the vehicle are not disrupted, which is

vital for the sports car's outstanding aerodynamic characteristics. In the

first phase of chassis development for the Mercedes-Benz McLaren 722 Edition,

various combinations of chassis parameters, such as springing and damping,

underwent a series of tests on the Formula 1 dynamometer in Woking. Then

the Mercedes-Benz and McLaren engineers made further refinements and finalised

the new set-up by performing an extensive series of tests on the road and,

above all, on the race track. The stiffer spring rates and shock absorber

characteristics of the chassis as well as the lowering of the body by 10

mm at both the front and rear are what gives the SLR 722 Edition its increased

directional stability and noticeably further enhanced handling dynamics.

Body roll on bends has been reduced by over 20 percent, allowing the new

SLR 722 Edition to corner at even greater speeds. New 19-inch forged aluminium

wheels also help to improve the handling dynamics of the special-edition

model, their unique, palladium grey design highlighting the car's motor-racing

heritage. Their lower weight compared to conventional wheels reduces the

unsprung masses, making the responsiveness of the SLR 722 Edition all the

sharper. Plus, the 19-inch wheels allow larger brake discs with a diameter

of 390 mm to be fitted on the front axle. Hailing from the Italian manufacturer

"Brembo", the new braking system combines with the carbon-fibre-reinforced

ceramic discs to provide formidable decelerating power which is fully in

keeping with the SLR 722 Edition's scintillating all-round performance.

Exhaustive testing was carried out to develop a new ESP® control system

for this new brake configuration. One of the main driving forces behind the enhanced

performance of the SLR 722 Edition is the retuned chassis. Development work

at McLaren's Formula 1 headquarters was based on the set-up of the SLR's

proven aluminium chassis, that is itself the handiwork of experienced race

car developers: wheel guidance is the task of double wishbones at both the

front and rear. The bottom links are arranged in such a way that the wheels

receive a negative camber when the springs compress or when cornering at

speed. This guarantees optimum contact with the road in any situation. Meanwhile,

the axle technology also minimises the degree of diving and squatting while

braking heavily and accelerating respectively. The axle's wishbones are made

from forged aluminium, while cast aluminium is used for the wheel carriers.

This lightweight material boasts a host of advantages compared to conventional

steel constructions, including the far superior response of the suspension

and damping that results from the reduced weight. The relatively long wheelbase

of 2700 millimetres likewise contributes to the exemplary handling

characteristics, with the most notable benefit being the outstanding

straight-line stability, while the wide track combines with the low centre

of gravity to enable high cornering speeds. The chassis construction has

the anti-roll bar positioned above the front axle where it is controlled

via rocker arms, just like on a Formula 1 car. With this setup , the anti-roll

bar does not take up any additional installation space. In this way, the

smooth lines of the underside of the vehicle are not disrupted, which is

vital for the sports car's outstanding aerodynamic characteristics. In the

first phase of chassis development for the Mercedes-Benz McLaren 722 Edition,

various combinations of chassis parameters, such as springing and damping,

underwent a series of tests on the Formula 1 dynamometer in Woking. Then

the Mercedes-Benz and McLaren engineers made further refinements and finalised

the new set-up by performing an extensive series of tests on the road and,

above all, on the race track. The stiffer spring rates and shock absorber

characteristics of the chassis as well as the lowering of the body by 10

mm at both the front and rear are what gives the SLR 722 Edition its increased

directional stability and noticeably further enhanced handling dynamics.

Body roll on bends has been reduced by over 20 percent, allowing the new

SLR 722 Edition to corner at even greater speeds. New 19-inch forged aluminium

wheels also help to improve the handling dynamics of the special-edition

model, their unique, palladium grey design highlighting the car's motor-racing

heritage. Their lower weight compared to conventional wheels reduces the

unsprung masses, making the responsiveness of the SLR 722 Edition all the

sharper. Plus, the 19-inch wheels allow larger brake discs with a diameter

of 390 mm to be fitted on the front axle. Hailing from the Italian manufacturer

"Brembo", the new braking system combines with the carbon-fibre-reinforced

ceramic discs to provide formidable decelerating power which is fully in

keeping with the SLR 722 Edition's scintillating all-round performance.

Exhaustive testing was carried out to develop a new ESP® control system

for this new brake configuration. |

>High-tech material for exemplary

safety and maximum strength

The high-performance sports car's bodyshell bristles

with high tech. The entire bodyshell, including the crash structures at the

front and rear, the occupant cell, the swing-wing doors and the bonnet, is

made from carbon-fibre-reinforced plastic (CRP). This lightweight yet, at

the same time, extremely rigid material is a technology borrowed from the

aviation and space travel industry and has already proven its worth in

ultra-sophisticated Formula 1 race cars. Despite the weightsaving of 50 percent

that this high-tech material represents compared to steel, it is just as

strong, which allowed the engineers to focus on achieving the body's enormous

strength. Plus, in the event of an impact, carbon fibres have a specific

energy absorption that is some four to five time higher than steel or aluminium.

Mercedes-Benz has capitalised on this material property by also fitting two

620-millimetre-long side member elements made from carbon fibre in the front

structure of the SLR 722 Edition; these are capable of absorbing all of the

impact energy in a head-on collision without exceeding the maximum levels

of deceleration that the occupants are able to withstand. In the event of

an impact, the fibres of these two elements tear from front to rear to crumple

in a carefully predetermined manner and thereby produce a constant rate of

deceleration. The super sports car's occupant cell is likewise made from

this high-tech material, offering passengers a very rigid and therefore safe

survival space in an accident. At the rear of the car, the task of absorbing

energy in a crash falls to two internal side members made from laminated

carbon fibre and a sturdy cross member, which together ensure that the occupant

cell remains virtually intact. The occupant protection system also encompasses

adaptive front airbags, which are deployed in two stages depending on the

severity of the impact, head/thorax bags and knee bags, as well as seat belt

tensioners and belt force limiters. The high-performance sports car's bodyshell bristles

with high tech. The entire bodyshell, including the crash structures at the

front and rear, the occupant cell, the swing-wing doors and the bonnet, is

made from carbon-fibre-reinforced plastic (CRP). This lightweight yet, at

the same time, extremely rigid material is a technology borrowed from the

aviation and space travel industry and has already proven its worth in

ultra-sophisticated Formula 1 race cars. Despite the weightsaving of 50 percent

that this high-tech material represents compared to steel, it is just as

strong, which allowed the engineers to focus on achieving the body's enormous

strength. Plus, in the event of an impact, carbon fibres have a specific

energy absorption that is some four to five time higher than steel or aluminium.

Mercedes-Benz has capitalised on this material property by also fitting two

620-millimetre-long side member elements made from carbon fibre in the front

structure of the SLR 722 Edition; these are capable of absorbing all of the

impact energy in a head-on collision without exceeding the maximum levels

of deceleration that the occupants are able to withstand. In the event of

an impact, the fibres of these two elements tear from front to rear to crumple

in a carefully predetermined manner and thereby produce a constant rate of

deceleration. The super sports car's occupant cell is likewise made from

this high-tech material, offering passengers a very rigid and therefore safe

survival space in an accident. At the rear of the car, the task of absorbing

energy in a crash falls to two internal side members made from laminated

carbon fibre and a sturdy cross member, which together ensure that the occupant

cell remains virtually intact. The occupant protection system also encompasses

adaptive front airbags, which are deployed in two stages depending on the

severity of the impact, head/thorax bags and knee bags, as well as seat belt

tensioners and belt force limiters. |

An aerodynamic work of art: even more

downforce and an improved cd figure

Around 100 hours of meticulous work in the wind tunnel also helped boost

the performance of the SLR 722 Edition. Here the developers performed yet

another technical masterstroke by increasing downforce whilst at the same

time reducing the cd (drag coefficient) figure. It's all thanks to the

air-splitter at the front end of the SLR 722 Edition. Consisting of carbon

with a clear-coat finish, the distinctively shaped spoiler lip not only enhances

aerodynamics, it also increases the downforce at the front axle by 128 percent.

Small wheel spoilers, also finished in carbon, reduce air swirl at the rear

axle, making for a smoother airflow and optimising road feel. The spoilers

combine with the airbrake at the rear to produce a further substantial gain

in the downforce acting at the rear axle of the new SLR 722 Edition. The

result is even more precise handling and turn-in at high speeds. The rear-mounted

airbrake is designed to optimise directional stability and braking power:

when the speed exceeds 120 km/h, it automatically rises up at an angle that

has been adjusted in line with the extremely dynamic performance of the new

model. If the driver hits the brakes hard at high speed, the airbrake tilts

up into the airstream automatically. This dynamic modification increases

rearaxle downforce within a fraction of a second, thus partially compensating

for the dynamic axle load distribution during braking, which presses towards

the front axle. A further factor which contributes to the distinctly

sports-oriented configuration is the weight of the SLR 722 Edition, which

the engineers have managed to reduce by around 44 kg. A lighter oil tank

and damper bodies made from aluminium, which have the added benefit of improving

the vibration response of the unsprung masses, contribute to this weight

loss. Last but not least, optimised panelling and insulating materials also

have a positive effect on the vehicle weight. Yet for all these measures,

the high levels of comfort, safety and practicality that have become Mercedes

hallmarks remain unaffected.

Sporty design through and through

In terms of exterior design, the SLR 722 Edition

features discreet sporty touches, thereby satisfying the desires of keen

gentleman drivers and affluent sports-car collectors – the core target

group – to the letter. The new-look 19-inch light-alloy wheels afford

a perfect view of the red-painted brake callipers and the large brake discs,

emphasising the sheer power and performance that underpins every aspect of

the SLR 722 Edition. In addition, individual components in carbon with a

clearcoat finish highlight the close ties with Formula 1. Plus, the grille-style

design of the black-painted air outlets on the bonnet, not to mention the

front and rear light clusters with their palladium grey surrounds, blend

in perfectly with the carbonfibre look. The SLR 722 Edition is available

with a crystal antimony grey paint finish which creates a vivid impression

of depth and produces an extremely intensive-looking surface structure. Moving

inside, the sports bucket seats, upholstered in a combination of semianiline

leather and Alcantara, offer excellent lateral support, while the colour

contrast provided by the distinctive "300 SL red" stitching throughout the

interior, the 722 insignia on the head restraints and the red seat belts

is designed for added visual impact. The attractive material mix comprising

semi-aniline leather and Alcantara, which gives the interior its characteristic

look and feel, also features prominently on the roof lining and door panels.

Frequently used controls, such as the shift lever and handbrake lever, are

trimmed in easy-grip, moisture-absorbing suede. The sporty design philosophy

that is at the heart of the SLR 722 Edition is also reflected by the widespread

use of carbon throughout the interior. This material, straight from the world

of Formula 1, lends the centre console an extremely puristic look. The restyled

instrument cluster focuses the driver's attention on the key vehicle data,

comprising classic-style round dials with a signal-red background. The

functionality of the multifunction display is given an extra sporty touch

in the form of the AMG RACETIMER. Finally, the designers paid special attention

to the steering wheel as the key link between driver and car: with its combined

leather/suede trim, the rim is extremely easy to grip and helps the driver

to stay in complete control when performing high-speed manoeuvres, as do

the new aluminium shift paddles. In terms of exterior design, the SLR 722 Edition

features discreet sporty touches, thereby satisfying the desires of keen

gentleman drivers and affluent sports-car collectors – the core target

group – to the letter. The new-look 19-inch light-alloy wheels afford

a perfect view of the red-painted brake callipers and the large brake discs,

emphasising the sheer power and performance that underpins every aspect of

the SLR 722 Edition. In addition, individual components in carbon with a

clearcoat finish highlight the close ties with Formula 1. Plus, the grille-style

design of the black-painted air outlets on the bonnet, not to mention the

front and rear light clusters with their palladium grey surrounds, blend

in perfectly with the carbonfibre look. The SLR 722 Edition is available

with a crystal antimony grey paint finish which creates a vivid impression

of depth and produces an extremely intensive-looking surface structure. Moving

inside, the sports bucket seats, upholstered in a combination of semianiline

leather and Alcantara, offer excellent lateral support, while the colour

contrast provided by the distinctive "300 SL red" stitching throughout the

interior, the 722 insignia on the head restraints and the red seat belts

is designed for added visual impact. The attractive material mix comprising

semi-aniline leather and Alcantara, which gives the interior its characteristic

look and feel, also features prominently on the roof lining and door panels.

Frequently used controls, such as the shift lever and handbrake lever, are

trimmed in easy-grip, moisture-absorbing suede. The sporty design philosophy

that is at the heart of the SLR 722 Edition is also reflected by the widespread

use of carbon throughout the interior. This material, straight from the world

of Formula 1, lends the centre console an extremely puristic look. The restyled

instrument cluster focuses the driver's attention on the key vehicle data,

comprising classic-style round dials with a signal-red background. The

functionality of the multifunction display is given an extra sporty touch

in the form of the AMG RACETIMER. Finally, the designers paid special attention

to the steering wheel as the key link between driver and car: with its combined

leather/suede trim, the rim is extremely easy to grip and helps the driver

to stay in complete control when performing high-speed manoeuvres, as do

the new aluminium shift paddles.

|

READER COMMENTS

| DaimlerChrysler Communications,

Stuttgart (Germany), Auburn Hills (USA), January 2007 |

BACK TO TOP

|