High-torque

V8 compressor engine with 460-kW/626-hp output

Drehmomentstarker V8-Kompressormotor mit 460 kW/626

PS |

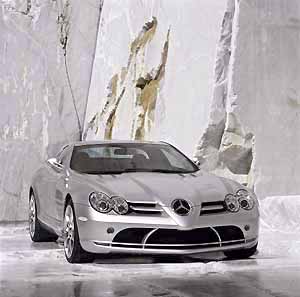

Mercedes-Benz SLR McLaren

-

0 to 100 km/h in 3.8 seconds

-

World's first series-produced car to have carbon fibre front crash

structure

-

High-performance brake discs made from fibre-reinforced ceramic

Stuttgart

- Back in the mid-1950s the three letters SLR acquired a hallowed status,

as a Mercedes-Benz racing car of that name set new standards in the world

of high-class Gran Turismo vehicles. Visually breathtaking and, thanks to

innovative technology, superior to its rivals in terms of performance and

handling, it spawned a legend. Mercedes-Benz and McLaren have successfully

imbued the new Mercedes-Benz SLR McLaren (due to make its debut in autumn

2003) with the same charismatic qualities. Just like its legendary predecessor

of 1955, this SLR incorporates new technological developments which are ahead

of their time. For evidence, simply take a glance under the bonnet at the

Mercedes-AMG V8 powerplant. With its 5.5-litre displacement and screw-type

compressor, the engine develops a peak output of 460 kW/626 hp

and delivers its maximum torque of 780 Newtonmetres from 3250 rpm

- a figure which remains constant across a broad engine speed range of up

to 5000 rpm. With this kind of power under the bonnet, the Mercedes-Benz

SLR McLaren delivers performance figures which are among the best in its

class: this high-performance sports car takes just 3.8 seconds to sprint

from 0 to 100 km/h, it passes the 200 km/h mark after

10.6 seconds, and from a standing start it takes just 28.8 seconds to

reach 300 km/h. The two-seater has a top speed of 334 km/h (provisional

figure). Stuttgart

- Back in the mid-1950s the three letters SLR acquired a hallowed status,

as a Mercedes-Benz racing car of that name set new standards in the world

of high-class Gran Turismo vehicles. Visually breathtaking and, thanks to

innovative technology, superior to its rivals in terms of performance and

handling, it spawned a legend. Mercedes-Benz and McLaren have successfully

imbued the new Mercedes-Benz SLR McLaren (due to make its debut in autumn

2003) with the same charismatic qualities. Just like its legendary predecessor

of 1955, this SLR incorporates new technological developments which are ahead

of their time. For evidence, simply take a glance under the bonnet at the

Mercedes-AMG V8 powerplant. With its 5.5-litre displacement and screw-type

compressor, the engine develops a peak output of 460 kW/626 hp

and delivers its maximum torque of 780 Newtonmetres from 3250 rpm

- a figure which remains constant across a broad engine speed range of up

to 5000 rpm. With this kind of power under the bonnet, the Mercedes-Benz

SLR McLaren delivers performance figures which are among the best in its

class: this high-performance sports car takes just 3.8 seconds to sprint

from 0 to 100 km/h, it passes the 200 km/h mark after

10.6 seconds, and from a standing start it takes just 28.8 seconds to

reach 300 km/h. The two-seater has a top speed of 334 km/h (provisional

figure).

In the interests of optimum weight distribution, optimum dynamic handling

and high stability on braking, the Mercedes-Benz SLR McLaren has a front

mid-engined design. The V8 powerplant is mounted on a robust aluminium frame

and has a low installation position. Water-type charge-air cooling, three

valves per cylinder, dry sump lubrication and four metal catalytic converters

are further special features of this powerful engine

- an engine which already meets stringent EU 4 exhaust

gas regulations which are not due to come into force until 2005.

Three transmission programs for short,

sporty gearshifts

The 5-speed automatic transmission, fitted as standard, is also designed

for high performance. It allows the driver to choose between three programs,

letting him or her determine the shift speed individually. When "Manual"

is selected, the five gears can either be shifted using buttons on the steering

wheel or using the selector lever's Touchshift function. In manual mode the

driver can select between three shift stages - "Sport", "SuperSport" and

"Race" - significantly shortening the shift times still further for an even

sportier drive.

High-tech material for exemplary safety

and outstanding rigidity

The

bodyshell of the high-performance sports car is also distinctly high-tech.

Along with the front and rear structure and the passenger cell, the swing-wing

doors and the bonnet, it is made entirely from carbon fibre composite. This

lightweight yet extremely rigid material originated in the aeronautical and

space industries and has also proven its benefits in today's Formula 1 race

cars. The weight advantage of the high-tech material over steel is around

50 percent. In addition to this, carbon fibres, on impact, are characterised

by four to five times higher energy absorption than steel or aluminium.

Mercedes-Benz exploits these qualities by inserting two 620-millimetre

longitudinal members made from carbon fibre in the front structure of the

new SLR. These absorb the entire energy of the crash in a head-on collision

without exceeding tolerable deceleration values for the occupants. In an

impact the fibres of these elements shred from front to rear with precisely

calculated deformation behaviour, ensuring constant deceleration. This makes

the SLR the world's first series-produced car to have a front crash structure

made entirely from carbon fibre. The carbon fibre longitudinal members each

weigh just 3.4 kilograms. The passenger cell of the high-performance

sports car is also made entirely from this high-tech material. In a head-on,

side-on or rear-end collision, it offers the passengers an extremely rigid,

safe survival zone. At the rear, two internal longitudinal members made from

laminated carbon fibre and a robust cross member take on the task of energy

absorption in the event of a crash - as a rule the passenger

cell remains structurally unaffected. Adaptive front airbags which

deploy in two stages depending on the severity of the accident, newly developed

sidebags which protect the head, plus belt tensioners and belt force limiters

all form part of the new SLR's occupant protection system. The

bodyshell of the high-performance sports car is also distinctly high-tech.

Along with the front and rear structure and the passenger cell, the swing-wing

doors and the bonnet, it is made entirely from carbon fibre composite. This

lightweight yet extremely rigid material originated in the aeronautical and

space industries and has also proven its benefits in today's Formula 1 race

cars. The weight advantage of the high-tech material over steel is around

50 percent. In addition to this, carbon fibres, on impact, are characterised

by four to five times higher energy absorption than steel or aluminium.

Mercedes-Benz exploits these qualities by inserting two 620-millimetre

longitudinal members made from carbon fibre in the front structure of the

new SLR. These absorb the entire energy of the crash in a head-on collision

without exceeding tolerable deceleration values for the occupants. In an

impact the fibres of these elements shred from front to rear with precisely

calculated deformation behaviour, ensuring constant deceleration. This makes

the SLR the world's first series-produced car to have a front crash structure

made entirely from carbon fibre. The carbon fibre longitudinal members each

weigh just 3.4 kilograms. The passenger cell of the high-performance

sports car is also made entirely from this high-tech material. In a head-on,

side-on or rear-end collision, it offers the passengers an extremely rigid,

safe survival zone. At the rear, two internal longitudinal members made from

laminated carbon fibre and a robust cross member take on the task of energy

absorption in the event of a crash - as a rule the passenger

cell remains structurally unaffected. Adaptive front airbags which

deploy in two stages depending on the severity of the accident, newly developed

sidebags which protect the head, plus belt tensioners and belt force limiters

all form part of the new SLR's occupant protection system.

Ceramic brake discs and

SBCTM for exemplary braking safety

The

brake discs of the cutting-edge swing-wing door vehicle are also made from

a high-tech material which meets the highest of standards. Here Mercedes-Benz

has used carbon fibre-reinforced ceramic to achieve outstanding performance,

temperature-resistance and longevity. Thanks to the highly robust material,

the SLR's large brake discs allow maximum deceleration of up to

1.3 g - a top value in a series-produced

car. At the front axle alone a total brake pad area of

440 cm2 is available. Further features of the new

SLR include Sensotronic Brake Control (the electrohydraulic braking system),

the Electronic Stability Program (ESP ®), automatic tyre pressure

monitoring, 18-inch wheels and aluminium suspension which bears the signature

of experienced race car constructors - all of which create the necessary

criteria for perfect dynamic handling and excellent driving safety. The

brake discs of the cutting-edge swing-wing door vehicle are also made from

a high-tech material which meets the highest of standards. Here Mercedes-Benz

has used carbon fibre-reinforced ceramic to achieve outstanding performance,

temperature-resistance and longevity. Thanks to the highly robust material,

the SLR's large brake discs allow maximum deceleration of up to

1.3 g - a top value in a series-produced

car. At the front axle alone a total brake pad area of

440 cm2 is available. Further features of the new

SLR include Sensotronic Brake Control (the electrohydraulic braking system),

the Electronic Stability Program (ESP ®), automatic tyre pressure

monitoring, 18-inch wheels and aluminium suspension which bears the signature

of experienced race car constructors - all of which create the necessary

criteria for perfect dynamic handling and excellent driving safety.

READER COMMENTS

| DaimlerChrysler Communications,

August 2003 |

BACK TO TOP

|