The

Stuttgart-based brand

CLS-CLASS

Effortless performance twinned with excellent fuel

economy

CLS-KLASSE

Gute Kombination: Souveränes Fahr-Erlebnis bei höchster

Wirtschaftlichkeit |

World premiere of an innovative direct petrol

injection system

Stuttgart - Following

intensive development work, Mercedes-Benz is now presenting the world's first

petrol engine with piezoelectric direct injection and spray-guided combustion.

This 215 kW/292 hp six-cylinder engine

will enter the market in the second half of 2006 in the CLS-Class. In the

European driving cycle, this innovative injection technology from Mercedes-Benz

achieves fuel consumption improvements of ten percent over the highly efficient

V6 petrol engine with port injection and fully variable valve timing: the

figures for the CLS 350 CGI are 9.1 litres per 100 km. Thus Mercedes-Benz

has succeeded in combining a substantial increase in output with a significant

increase in fuel economy. This pioneering injection system is another

trend-setting technology from Mercedes-Benz. It achieves much better fuel

efficiency, and thus also higher thermodynamic efficiency, than conventional

wall-guided direct injection systems. The new system will form the basis

for future engine development work in this output class. The main advantage

of the CGI engine (CGI = Stratified-Charged Gasoline Injection) lies in the

stratified operating mode from which it takes its name. During this mode

the engine is run with high excess air and thus excellent fuel efficiency.

Now, thanks to multiple injection, it is for the first time possible to extend

this lean-burn operating mode to higher rpm and load ranges too. During each

compression stroke, a series of injections takes place, spaced just fractions

of a second apart. This has the effect of significantly improving mixture

formation, combustion and fuel consumption. While stratified charge operation

was previously only possible in the low part-load range, the new Mercedes

direct-injection engine can still operate in this lean-burn stratified mode

at speeds in excess of 120 km/h. When driving on main roads and motorways

at largely constant speed and with proper anticipation, the CGI engine

outperforms the fuel economy of the six-cylinder engine with conventional

injection technology by up to 1.5 litres per 100 km, a saving of up to 15

percent. This 215 kW/292 hp six-cylinder engine

will enter the market in the second half of 2006 in the CLS-Class. In the

European driving cycle, this innovative injection technology from Mercedes-Benz

achieves fuel consumption improvements of ten percent over the highly efficient

V6 petrol engine with port injection and fully variable valve timing: the

figures for the CLS 350 CGI are 9.1 litres per 100 km. Thus Mercedes-Benz

has succeeded in combining a substantial increase in output with a significant

increase in fuel economy. This pioneering injection system is another

trend-setting technology from Mercedes-Benz. It achieves much better fuel

efficiency, and thus also higher thermodynamic efficiency, than conventional

wall-guided direct injection systems. The new system will form the basis

for future engine development work in this output class. The main advantage

of the CGI engine (CGI = Stratified-Charged Gasoline Injection) lies in the

stratified operating mode from which it takes its name. During this mode

the engine is run with high excess air and thus excellent fuel efficiency.

Now, thanks to multiple injection, it is for the first time possible to extend

this lean-burn operating mode to higher rpm and load ranges too. During each

compression stroke, a series of injections takes place, spaced just fractions

of a second apart. This has the effect of significantly improving mixture

formation, combustion and fuel consumption. While stratified charge operation

was previously only possible in the low part-load range, the new Mercedes

direct-injection engine can still operate in this lean-burn stratified mode

at speeds in excess of 120 km/h. When driving on main roads and motorways

at largely constant speed and with proper anticipation, the CGI engine

outperforms the fuel economy of the six-cylinder engine with conventional

injection technology by up to 1.5 litres per 100 km, a saving of up to 15

percent.

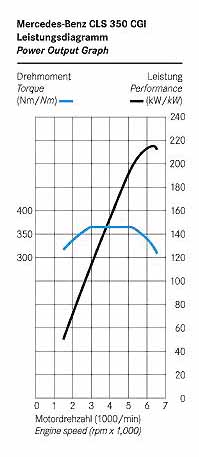

Effortless performance twinned with

excellent fuel economy

Low fuel consumption and excellent power delivery

are not at odds with each other on the second-generation Mercedes-Benz direct

petrol injection model. On the contrary, the engine delivers 15 kW/20 hp

more power than the conventional-injection V6 and four percent more torque.

Thus the V6 combines its excellent fuel economy with a level of effortless

driving enjoyment that is unprecedented in the six-cylinder segment. The

CLS 350 CGI accelerates from 0 - 100 km/h in just 6.7 seconds and has an

electronically gov-erned top speed of 250 km/h. The key figures for the new

CGI engine are: Low fuel consumption and excellent power delivery

are not at odds with each other on the second-generation Mercedes-Benz direct

petrol injection model. On the contrary, the engine delivers 15 kW/20 hp

more power than the conventional-injection V6 and four percent more torque.

Thus the V6 combines its excellent fuel economy with a level of effortless

driving enjoyment that is unprecedented in the six-cylinder segment. The

CLS 350 CGI accelerates from 0 - 100 km/h in just 6.7 seconds and has an

electronically gov-erned top speed of 250 km/h. The key figures for the new

CGI engine are:

• Displacement 3498 cc

• Compression ratio 12.2:1

• Rated output 215 kW/292 hp at 6400 rpm

• Rated torque 365 Newton metres at 3000-5100 rpm

With a fuel consumption of 9.1 - 9.3 litres per 100 kilometres (NEDC combined

cycle), the four-door Coupé has a range of approximately 870 kilometres

on one tank filling (80 litres). |

Pioneering invention: outward-opening

piezoelectric injectors

The most important components of this innovative direct petrol injection

system are the fast-acting, high-precision piezoelectric injectors. It is

on this invention and the way it has been translated into series-production

technology that the most important advances associated with spray-guided

combustion are based. The piezoelectric valves have injectors which open

outwards to create an annular gap just a few microns wide. This gap shapes

the fuel jet and produces a uniform, hollow-cone-shaped spray pattern. The

microsecond response times of the piezoelectric injectors provide the basis

for delivering multiple injections per compression stroke, and thus for lean-burn

operation. By allowing flexible and efficient control of the combustion process

they play a key part in ensuring the engine's outstanding fuel efficiency.

With the aid of simulations for the fuel mixture and the combustion process,

the pistons have been designed with special piston bowl geometry which

concentrates the lean mixture in the area around the spark plug and prevents

it from spreading out towards the cylinder wall. The piston shape therefore

also plays its part in en-suring near-total combustion, low fuel consumption

and low emissions in the direct-injection petrol engine. A high-pressure

pump and downstream fuel rail and pressure control valve are responsible

for delivering the fuel and regulating the quantity supplied. The peak fuel

pressure in this system is up to 200 bar - around 50 times the fuel pressure

in a conventional petrol injection system.

Dual effect: low engine-out emissions

and high exhaust temperatures

The Mercedes-developed combustion process

featuring multiple closely spaced in-jections on each compression stroke

also results in smoother operation and improved emissions performance.

Measurements show that engine-out hydrocarbon emis-sions in the warm-up phase

are almost halved. Furthermore, since the injection and combustion processes

can be actively controlled, it is also possible to raise temperatures in

the exhaust manifold and thus speed catalytic converter warm-up. Just ten

seconds after starting from cold, the direct-injection petrol engine reaches

an exhaust temperature of over 700 degrees Celsius. Emissions are controlled

by two close-coupled three-way catalytic converters with linear oxygen sensor

control, which goes into operation immediately after the en-gine starts from

cold. To reduce nitrogen oxide emissions, Mercedes-Benz has adopted a two-part

strategy. This comprises, firstly, dual electrically controlled and cooled

exhaust gas recirculation which, depending on engine operating conditions,

redirects up to 40 percent of the exhaust gases back into the cylinders.

Secondly, it also comprises two underfloor NOx storage-type catalytic converters.

Under lean operating conditions, these converters adsorb the nitrogen oxides.

Periodically, during brief regeneration pulses, the nitrogen oxides are then

desorbed, reacting with other exhaust gas constituents to form harmless nitrogen.

Sensors upstream and down-stream of the catalytic converters monitor their

operation. In addition, the new CGI engine also incorporates the same unique

package of high-tech features as its conventional-injection counterpart.

This includes four-valve cylinder heads, variable intake and exhaust camshaft

timing, a two-stage in-take manifold, balancer shafts and intelligent thermal

management with an electronically controlled thermostat. The crankcase and

cylinder heads are of alumin-ium and the cylinder liners are of low-friction,

thermally resistant, lightweight aluminium-silicon alloy. All fuel-carrying

components of the CGI engine are of high-grade steel or brass; the rails

in the area of the two cylinder banks and the housing of the high-pressure

pump are of forged stainless steel. The new CLS 350 CGI is designed to operate

on sulphur-free unleaded premium fuel and its state-of-the-art technology

gives it the potential to adapt to emissions standards of the future. The Mercedes-developed combustion process

featuring multiple closely spaced in-jections on each compression stroke

also results in smoother operation and improved emissions performance.

Measurements show that engine-out hydrocarbon emis-sions in the warm-up phase

are almost halved. Furthermore, since the injection and combustion processes

can be actively controlled, it is also possible to raise temperatures in

the exhaust manifold and thus speed catalytic converter warm-up. Just ten

seconds after starting from cold, the direct-injection petrol engine reaches

an exhaust temperature of over 700 degrees Celsius. Emissions are controlled

by two close-coupled three-way catalytic converters with linear oxygen sensor

control, which goes into operation immediately after the en-gine starts from

cold. To reduce nitrogen oxide emissions, Mercedes-Benz has adopted a two-part

strategy. This comprises, firstly, dual electrically controlled and cooled

exhaust gas recirculation which, depending on engine operating conditions,

redirects up to 40 percent of the exhaust gases back into the cylinders.

Secondly, it also comprises two underfloor NOx storage-type catalytic converters.

Under lean operating conditions, these converters adsorb the nitrogen oxides.

Periodically, during brief regeneration pulses, the nitrogen oxides are then

desorbed, reacting with other exhaust gas constituents to form harmless nitrogen.

Sensors upstream and down-stream of the catalytic converters monitor their

operation. In addition, the new CGI engine also incorporates the same unique

package of high-tech features as its conventional-injection counterpart.

This includes four-valve cylinder heads, variable intake and exhaust camshaft

timing, a two-stage in-take manifold, balancer shafts and intelligent thermal

management with an electronically controlled thermostat. The crankcase and

cylinder heads are of alumin-ium and the cylinder liners are of low-friction,

thermally resistant, lightweight aluminium-silicon alloy. All fuel-carrying

components of the CGI engine are of high-grade steel or brass; the rails

in the area of the two cylinder banks and the housing of the high-pressure

pump are of forged stainless steel. The new CLS 350 CGI is designed to operate

on sulphur-free unleaded premium fuel and its state-of-the-art technology

gives it the potential to adapt to emissions standards of the future.

In Western Europe, the CLS direct petrol injection model will replace the

current CLS 350.

| DaimlerChrysler Communications,

Stuttgart (Germany), Auburn Hills (USA), March 2006 |

BACK TO TOP |